60 MINUTE FIRE DOORS – FRAME EDGE GAP SEALANTS

In this Bitesize CPD we will be looking at expanding fire foam used for filling gaps between frame and substrate.

Use of expanding fire foam is rarely as specified on the fire door certificate and it’s use is commonly picked up by FCM’s Clerks of Works during their site inspections.

I am sure that we have all seen this before:

Expanding pink foam squirted into oversized gaps around fire doors

Here’s another “finished” article where we had the architraves removed for inspection behind

There are many opinions but what do the fire door manufacturers who make and certify the doors say? After all, if we want to install compliant fire doors, we should follow the manufacturers, certified and tested guidelines should we not?

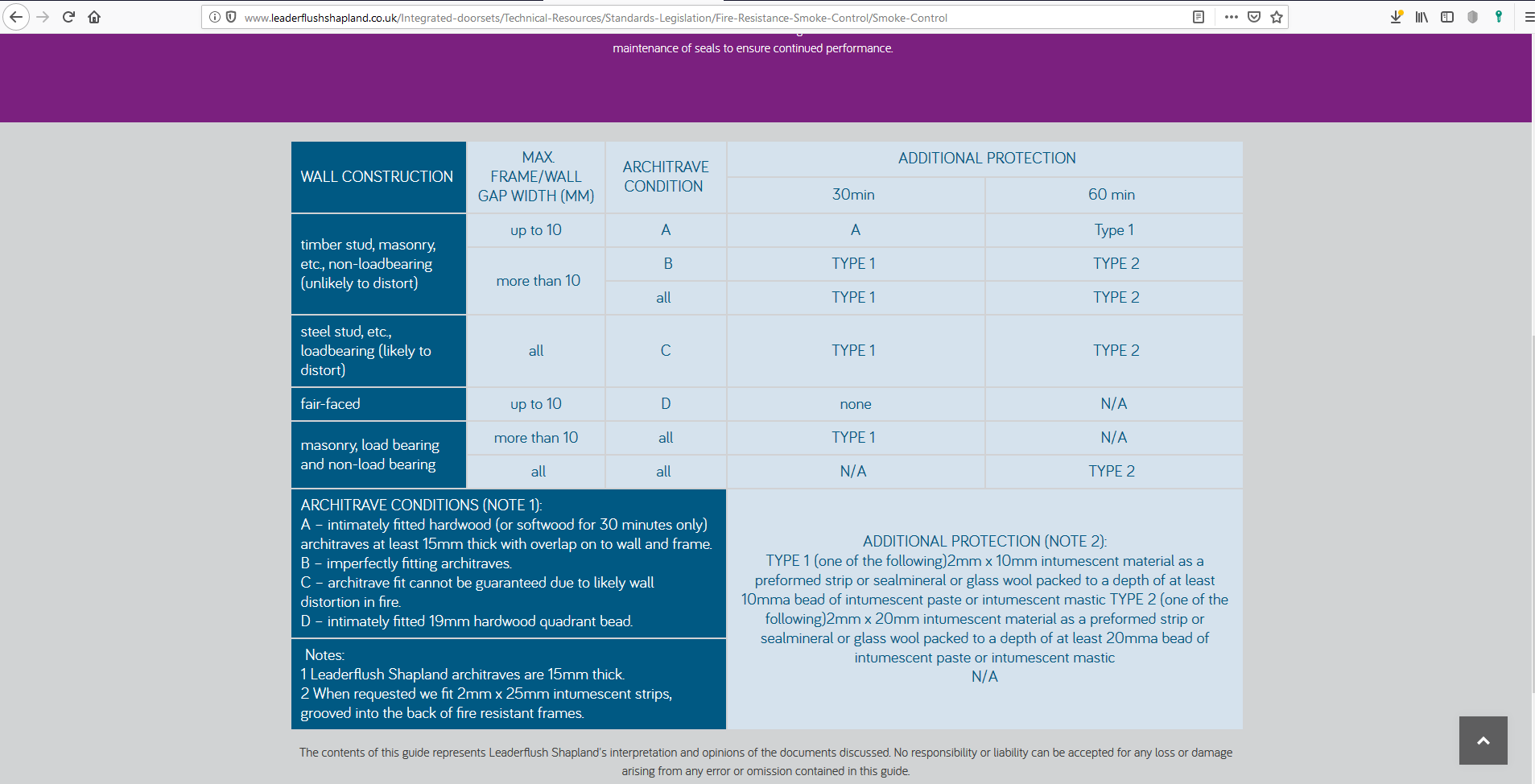

If we look at Leedaflush and Premdoor (along with many others) they state very clearly that the gaps, under most circumstances should be packed either with a proprietary pre formed intumescent strip or glass wool (rockwool) with an intumescent mastic bead over.

Rockwool packing with mastic bead over

Leedaflush installation instructions:

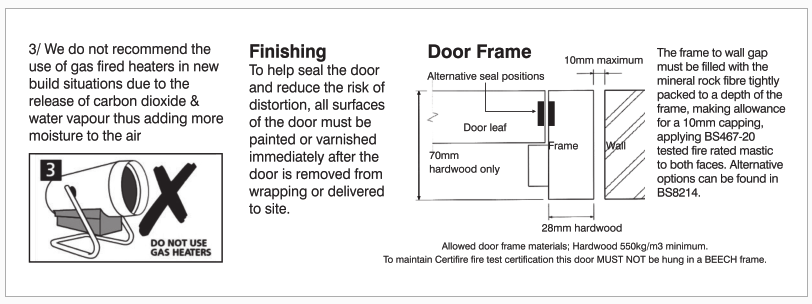

Premdoor installation instructions:

Expanding fire foam

Fire foam manufacturers will say that their products are fire rated but when you look into it most state that they are for a gap in a wall which must be a minimum of 100mm thick.

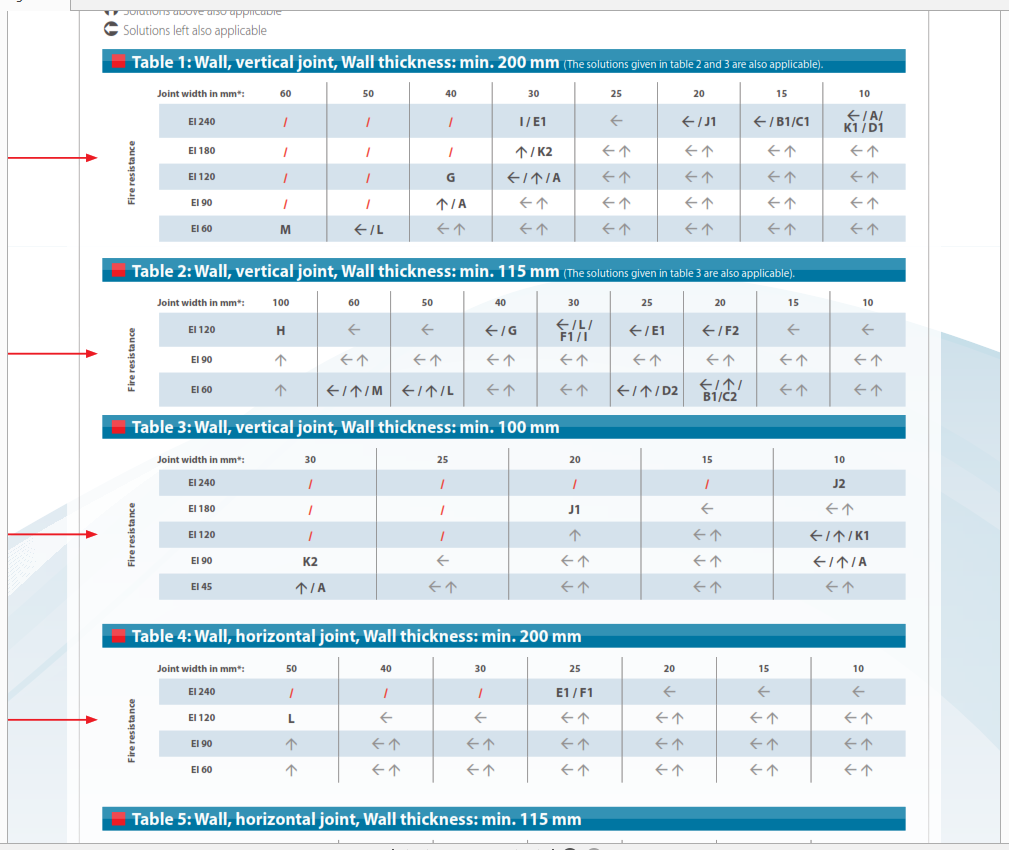

The tests are also carried out with timber doors into brick or concrete walls as noted below from the Soudal Fire catalogue.

* The test results are valid in cellular concrete, concrete and brick. All systems can also be used for joints with smoke and gas tightness requirements. The solutions applicable for 100mm are also applicable for wall thickness of 115 mm and 200mm. The solutions applicable for 115 mm are also applicable for 200mm but not for 100 mm. *

Soudal fire foam chart:

I have written to many foam manufacturers asking what is the situation with a door frame into a 2.8m high metal stud and plasterboard partition and am yet to receive an answer. We have to draw our own conclusions.

Blue 60 Foam:

Blue 60 claim that their foam is 60 minutes rated but their intumescent packers must be used.

They also state that as they have not tested their product with mastic it can not be used.

From the Blue 60 data sheet, again the frame and foam must be a minimum of 100mm thick.

However, in order to comply with the tests carried out the foam must fill all gaps and have no voids. How do we ensure that this is carried out and checked on site?

Conclusions

From BS 8214:2016

*Use (of mastic or expanding foam) is conditional on the mastic or expanded foam having test evidence for the structure that is being used (e.g. timber to concrete, concrete to concrete, flexible partition to timber, flexible partition to concrete). Restrictions apply unless appropriate test evidence is available.*

We are usually offered a solution which is easiest for the installers.

We have to decide whether we are going to insist on fire doors being installed to comply with testing and certification by their manufacturers.

How many of your projects are fitting fire doors into metal stud and plasterboard partitions? Are all metal stud walls the same?

The only way to know for sure is to ask for certification that testing was carried out (and passed) on full sized installations rather than small scale test rigs. Have the tests behind the claims been carried out on a 2.8m high stud wall with expanding foam?

This was part of the Grenfell issue: Non compatible parts being put together because they were individually ok.

If we had to stand up in a court and state why we had made a decision that allowed the fire doors to be fitted contrary to manufacturers testing and certification, what would we say? It was easier for the installer?

Far better to insist that installation complies with the certificate’s installation instructions unless the installer can prove that their proposed method is better than that certified by the door manufacturer. Claims made in leaflets given out with boxes of expanding foam do not cut it.

Watch the short video below and decide where you want to stand

Steve Farrell

T: 07714234380

E: stevefarrell@fcmltd.co.uk

L: linkedin.com/in/stevefarrellfcmFox Curtis Murray are a building consultancy specialising in providing Clerks of Works services and Quality Control inspections.

- Subscribe to Our Newsletter