FIRE BATT INSTALLATION

In this Bitesize CPD we will be looking at correctly, installing a fire bat into a wall.

These are routinely fitted incorrectly and are very common defects picked up by FCM’s Clerks of Works during their site inspections.

Here is how not to do it!

Defects:

1. Small pieces instead of single batt.

2. Perimeters of batt not coated with ablative paste.

3. Raw edges visible.

4. Incorrectly applied intumescent mastic.

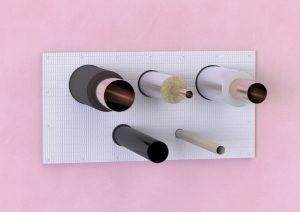

Fire batt is a high density mineral fibre board coated either on one or both sides with intumescent mastic that gives up to 4 hours fire and smoke protection during a fire.

This makes it a great option for sealing around penetrations in walls and floors.

It is available in 1200mm x 600mm and either 50mm or 60mm.

The board changes into a hard ceramic in the heat of a fire which then prevents fire travelling through holes in walls.

Batts must be cut to the largest possible section size and therefore not made up of little pieces.

All cut edges must be coated with ablative intumescent paste and stuck together so that they form a single slab.

Enornmous pressures build up during fires and the batt will be pushed out of the wall if not installed correctly allowing the rapid spread of fire.

There must be no visible raw edges with the rockwool insulation showing like the above.

Manufacturers guidelines expect it to look like the picture below:

Installation of fire stopping products in not a job for the site labourer or to be pushed onto the dry liners.

It is a skilled job requiring experience and knowledge.

When interviewing contractors, we should be questioning them on how they intend to provide certified, fire proof walls and compartments and not just hoping for the best.

Installations like the above, spotted late will cause delay in the completion of projects while ceilings are removed to provide access for correct installation.

Don’t be caught out on your projects.

Below is a 4-minute video showing how this important and complex process is carried out correctly. When you have seen it you will have a good understanding of how it should be done and what a correctly installed system should look like. It even has a nice bit of music to help it along.

Steve Farrell

T: 07714234380

E: stevefarrell@fcmltd.co.uk

L: linkedin.com/in/stevefarrellfcmFox Curtis Murray are a building consultancy specialising in providing Clerks of Works services and Quality Control inspections.

- Subscribe to Our Newsletter